Guidelines on Use of Exposure Control Measures

This document describes considerations and requirements of payment for temporary traffic control (TTC). The document offers several recommended methods and presents the advantages and disadvantages of each. Also addressed are techniques the agency and the contractor can use to monitor the effectiveness of selected methods.

This document is organized into the following sections:

- Examples of Exposure Control Measures

- Full Road Closures - Diversions

- Median Crossovers

- Ramp Closures

- Rolling Roadblocks

- Working During Nighttime Hours

- Accelerated Construction Techniques - Selecting and Implementing Exposure Control Measures

- Table of Benefits and Implementation Factors for Various Measures

- Examples: Minnesota, Oklahoma, Iowa, Florida, Washington

|

||

is critical that the project meet the deadline established and publicized for reopening the road.

|

||

reducing the impacts on nearby alternative routes.

|

||

Ramp closures require consideration of the effects of detoured traffic on nearby local streets, emergency vehicle routes, and local businesses and residents. Adequate signing regarding alternate entrances and exits must also be provided. In some cases, trailblazing signs to the alternate ramps may be required. Failure to properly notify motorists of an exit ramp closure may actually increase work zone exposure by causing drivers who were planning to exit to instead travel through the work zone before exiting at the next downstream ramp.

|

|

|

|

||

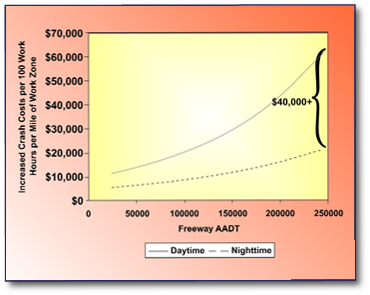

Financial incentives can also be created for contractors to be innovative and aggressive when developing project schedules, or can be used as financial disincentive if a proposed completion schedule is not met. Each hour that a project is reduced in duration results in potential crash savings to motorists and workers.

|

|

Finally, it is also important that the work be carefully planned, with appropriate safety precautions incorporated, to ensure production pressures do not lead to shortcuts that reduce safety or increase risk to workers.

Benefits and Implementation Factors for Various Exposure Control Measures

section of trunk Highway 36, a primary commuter route in St. Paul. A number of innovative construction

techniques and traffic management strategies were employed, as well as contract incentives. The project was highly successful in many ways. Construction time was reduced from 19 months (for traditional construction methods) to only 6.5 months during the full road closure, which resulted in less traffic impact than would have otherwise occurred. No worker injuries or traffic incidents were reported during the project. A strong public

information campaign generated positive support for the strategy. A total of 90 percent of residents and com- muters gave the project positive ratings and 83 percent of the local businesses were pleased with the approach.

projects based on the potential for congestion or safety problems. To implement the policy, the DOT is required to conduct a public hearing for the surrounding neighborhoods to notify the public of the upcoming ramp

closure(s) and to address concerns expressed by the public. Initially, this hearing was conducted just prior to closing the ramp(s). However, the DOT is working to conduct hearings earlier in the planning and design phase to ensure that all local concerns are addressed and no economic hardship is created for the local economy by closing the ramp(s).

Developed By:

The Roadway Safety Consortium

202-628-5465

www.workzonesafety.org

This material is based upon work supported by the Federal Highway Administration under Grant Agreement No. DTFH61‐06‐G‐00007.

Any opinions, findings and conclusions or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the Federal Highway Administration. This publication does not constitute a national standard, specification or regulation.

VALID HTML

VALID CSS

508 WAI